As a passionate manufacturer of materials, de Cavis develops and manufactures innovative processes and products in the materials sector. The journey often starts with a basic technology, which is then progressively developed into a manufacturing process and a specific product according to customer requirements.

Our main focus is the development and marketing of our patented foaming technology for the production of highly porous mineral materials with air contents between 50 and 95 vol% and the development of ceramic floats for underwater vehicles, as well as the production of high-purity and ultra-high-purity magnesium.

We are happy to assist you in the further development and marketing of your technology or product.

In addition to our development services, we also draw on our experience and broad expertise in the characterization of materials, material processing, and manufacturing processes for providing services and advice.

PRODUCTS

de Cavis offers a wide range of ceramic refractory bricks and hydraulically-bonded porous materials for a variety of potential applications, as well as ultra-high-purity 4N5 magnesium in the form of wire or in custom formats.

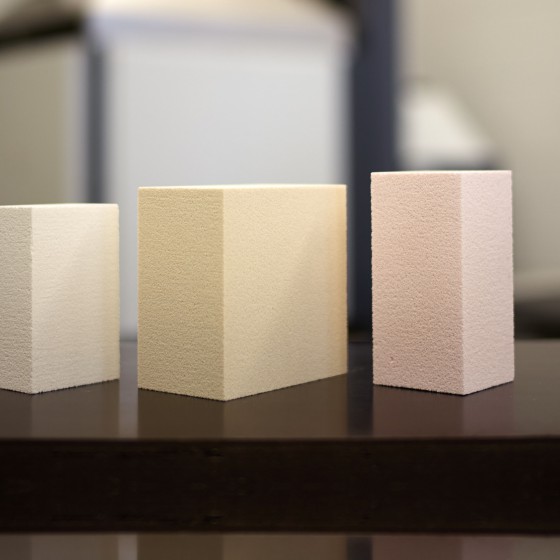

- REFRACTORY BRICKS FOR APPLICATION TEMPERATURES UP TO 1700°C

Our refractory materials are characterized by an extremely homogeneous microstructure, low weight, good mechanical strength, low thermal conductivity and good machinability. They are also free of fibers and hazardous substances. The density can be anywhere from 1500kg/m3to 200kg/m3and can be adjusted precisely, according to customer requirements. Even more complex geometries and larger formats are conceivable in addition to semi-standard blocks.

The potential field of application for our lightweight materials is broad and we always strive to adapt the material properties to your requirements.

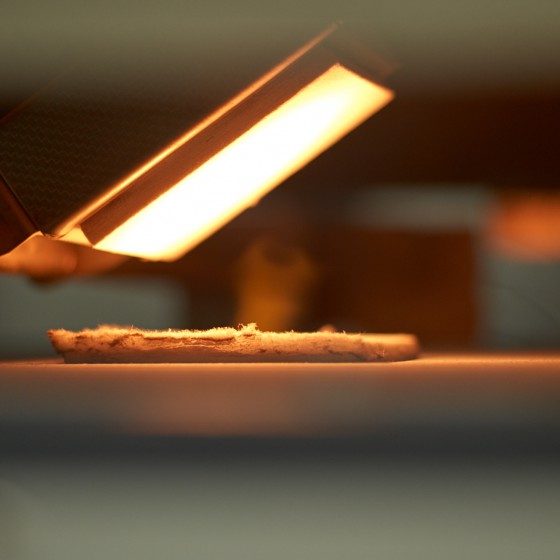

- HYDRAULICALLY BONDED HEAT INSULATION AND FIRE PROTECTION MATERIALS

Our hydraulically bonded porous materials are typically based on calcium aluminate, Portland cement, gypsum or similar materials. Depending on the application and material requirements, they have densities in the range of 80 to 1200kg/m3. Our foaming and manufacturing process also allows the production of large or complex formats.

Typical potential application areas of our hydraulically bound mineral materials are building insulation and fire protection.

- XHP-Mg: ULTRA-HIGH-PURITY MAGNESIUM

The technology for producing our ultra-high-purity magnesium was developed by ETH Zurich’s Laboratory of Metal Physics and Technology. de Cavis is a licensee of this technology and is responsible for its development and commercialization.

Our 4N5 XHP-Mg meets the highest material purity requirements and contains impurities of less than 100ppm. In particular, it is characterized by a very low average iron content of 0.6 ppm and aluminum content of 0.5 ppm. At the moment, we are producing 3 and 10-mm diameter wires. On request, diameters of 6 and 20mm as well as other formats up to 1kg are also possible.

Furthermore, we offer high-purity magnesium in various formats.

DEVELOPMENT AND SERVICES

de Cavis accompanies you from the first conception of your new application through the definition of the desired material properties and the right choice of material up to the scaling to production scale, and performs the material and process development purposefully for you, with attention to quality. Your needs and wishes are always the focus of our work.

Since the basic development and patenting of our foaming technology, we are constantly working on its further development in order to meet our customers’ requirements and their respective application. de Cavis is exclusive licensee of the foaming technology and has the right to grant sublicenses.

Working closely with ETH Zurich’s Laboratory of Metal Physics and Technology, we continue to develop ultra-high-purity magnesium technology to meet ever-increasing material requirements and open up new markets.

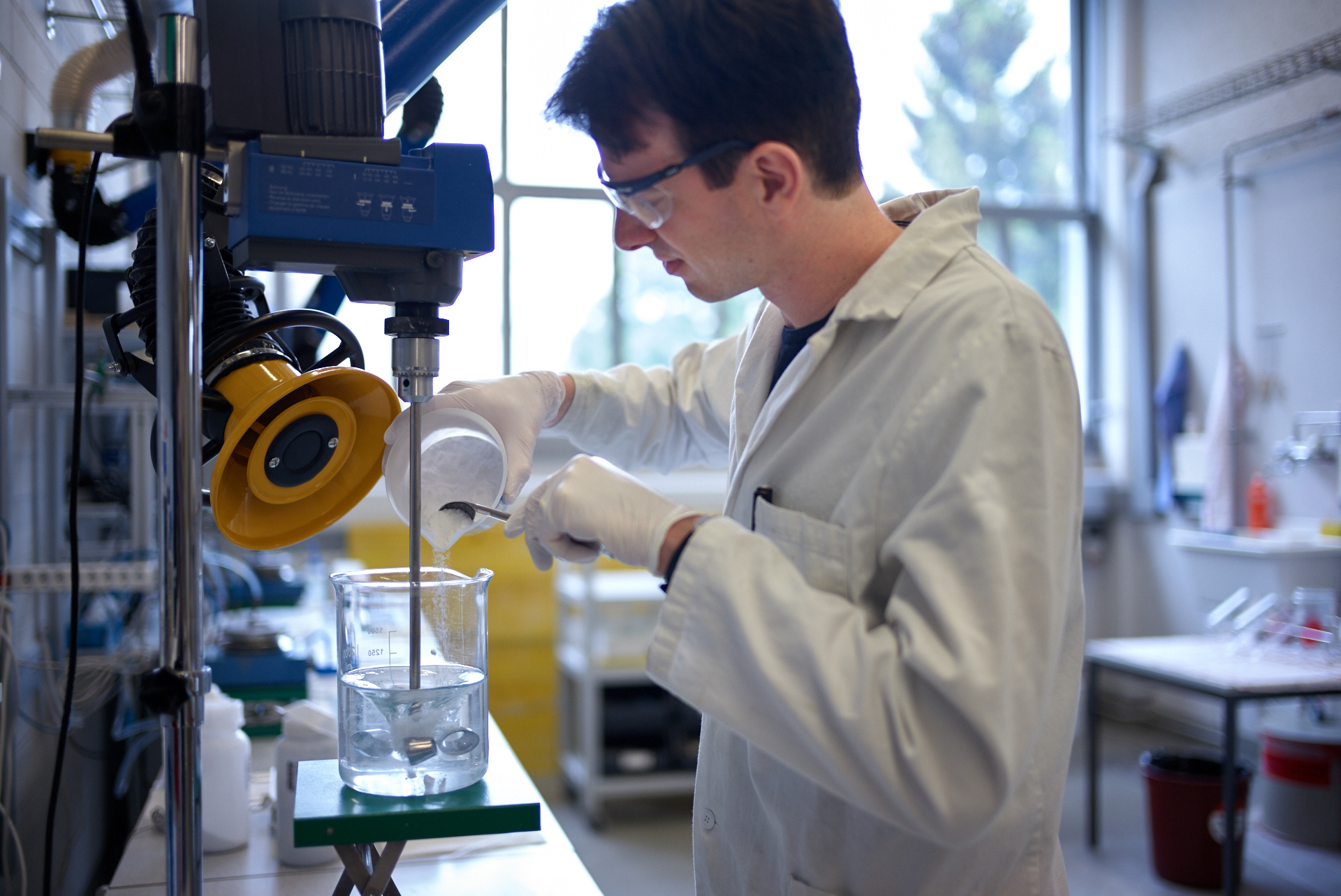

- DEVELOPMENT AND PRODUCTION OF HIGHLY-POROUS CERAMIC MATERIALS

de Cavis’ unique foaming technology owes its origin to an accidental discovery in the research group of Prof. Ludwig Gauckler at ETH Zurich and was subsequently co-developed and patented by Dr. Gonzenbach as part of his doctorate. The technology is based on the stabilization of water-based foams by fine particles. This results in wet foams, which due to their exceptional long-term stability, can be converted into solid components that meet the highest demands for microstructure quality and homogeneity. Here, a targeted adjustment of the material density is just as possible as a wide variation of the pore structure and pore size. Even with large components, the closed or open-pored microstructure is incomparably homogeneous, allowing reliable component properties to be generated.

The universal character of the foaming technology enables the development and production of porous materials from various raw materials such as alumina, silica, aluminosilicates, zirconia, calcium aluminate cement, Portland cement or gypsum. The foaming technology has also been extended to various polymers and metals as well as polymer-ceramic composites. More information can be found on our publication page. Due to the wide selection of materials, there are hardly any limits to the possible applications.

The porous materials developed by de Cavis stand out due to their light-weight, excellent mechanical, thermal and electrical properties, as well as their precise machinability. In addition, they are not flammable, have no health impacts, and are free from mineral fibers. Possible application examples of our foaming technology can be found in the area of high-temperature insulation, building insulation, fire and sound insulation as well as medical technology as a bone substitute material.

In addition to the actual foaming process, de Cavis also deals intensively with the shaping of these materials. In doing so, we’ve set ourselves the goal to manufacture not only simple shaped components, such as standard and semi-standard bricks, but also larger formats, as well as more complex geometries, through our technology.

- DEVELOPMENT AND PRODUCTION OF ULTRA-HIGH-PURITY MAGNESIUM

Ultra-high-purity magnesium (>99.99%) has great market potential in areas such as the semiconductor or medical industry. de Cavis develops, produces and distributes ultra-high-purity magnesium in close collaboration with ETH Zurich’s Laboratory of Metal Physics and Technology. The patented manufacturing process is based on a vacuum distillation of magnesium and was largely developed by Professors Jörg Löffler and Peter Uggowitzer as well as by Christian Wegmann. With a purity level of up to 99.995% and availability on a kilogram scale, our material stands out qualitatively and quantitatively from all previous ones. The material is produced in a first step as a semi-finished product in ingot form and then converted into various geometries. Blocks and rods are just as conceivable as wires of various diameters. We also manufacture special formats upon request. Through constant development of the manufacturing process we are succeeding in steadily improving the material quality as well as the production capacity. We are happy to be inspired by your ideas and needs and always take care to produce the optimum shape and quality for you.

We are currently working on a manufacturing process for XHP-Mg single crystals with a defined crystallographic orientation.

de Cavis is the exclusive licensee of this manufacturing technology in areas outside of medical technology. In the field of medical technology, there is a non-exclusive license, with the exception of cardiovascular implantsand osteosynthesis systems.

- DEVELOPMENT OF LOW COST CERAMIC BUOYANCY SPHERES FOR UNDERWATER VEHICLES AND EQUIPMENT

Deep sea mining takes place in ever-increasing depths of water, as the easily usable supplies are slowly exhausted. However, technical limitations currently prevent drilling at depths greater than three thousand meters. Due to the high dead weight and the heavy use of the steel drill pipe, there is a risk of component failure when drilling at such depths. The goal of developing new buoyancy spheres is to reduce stress and prevent failure.

de Cavis is part of the European Union funded development project CeraSphere. The aim of the project is to develop low-cost ceramic hollow spheres and their manufacturing technology. Such high-strength hollow spheres are to be installed in a systematic manner in buoyancy modules and should allow drilling in sea depths of more than three thousand meters.

The consortium consists of four small and medium-sized companies from Switzerland, Great Britain and Norway, two development partners and Trelleborg as a potential end-user. As a specialist in the field of application-oriented development of ceramic suspensions and associated molding processes, de Cavis brings its expertise to the achievement of ambitious technological project goals. To this end, we’re working closely together with our project partner High-performance Ceramicsof Empa Dübendorf.

Oil and Gas Exploration Expertise Running Deep (Oil & Gas Connect Issue 16)

Oil and Gas Exploration Expertise Running Deep (Oil & Gas Connect Issue 16) - MATERIAL CHARACTERIZATION

Material characterization is a key element in the development of novel ceramic materials. Every development activity starts with a high-quality analysis of raw materials, which is indispensable for a successful project implementation. We determine particle size distribution, specific surface area and surface charge of powders. In addition, we analyze the sintering behavior of ceramic green bodies by means of dilatometry and the final microstructure by means of light or scanning electron microscopy. On request, the rheological behavior of ceramic suspensions can be determined, and phase analysis can be performed by means of XRD.

TECHNOLOGY AND MATERIAL CONSULTING

We look forward to advising you on questions regarding ceramic materials, their properties and processing. Our many years of experience as an inventor and developer of ceramic materials provide us with a broad range of expertise and give us access to a large network within the industry and the university landscape. Upon request, we also offer technology research and assessments as well as failure analysis.

CONTACT

de Cavis AG

Im Schossacher 21

CH-8600 Dübendorf

Switzerland

email: info@decavis.com